AUTOMOBILE

A Guide To Vehicle Replacement Cycles For Rookie Fleet Managers

As the age of a vehicle increases, the maintenance costs and depreciation also increase significantly. This replacement journey becomes a hectic job for the rookie fleet managers on the field.

Since it is your responsibility as a fleet manager to address the inefficiencies of an old vehicle, introducing or revamping your fleet vehicle replacement strategy can save you all the hassle.

This article provides a complete guide to vehicle replacement cycles that help you operate your fleet as smoothly as possible.

Why Does Your Fleet Need Vehicle Replacement Cycles?

Regardless of the method you use to procure vehicles, optimization is necessary for understanding the nuances of your fleet life cycle and thus make an appropriate decision in repairs and upkeep.

Here’s what optimized replacement cycles for your fleet offer your business in the long run:

Reduced Downtime And Repair Costs

Forward-thinking companies are beginning to take notice of fleet replacement cycles to lower their preventative maintenance costs and increase their resale values.

If you would like to replace a few older vehicles in your fleet, following a fixed timeline will ensure you do so before the truck stalls or undergoes breakdowns out of warranty.

Replacing older trucks before major problems arise also decreases losses due to downtime, thereby improving efficiencies across fleet operations.

Increased Productivity

Fleet managers understand that modern vehicles will enable truckers to be more productive. The technological improvements and overall comfort of the latest models will drive fleet operators to perform better at work.

Thus, by determining a proper cycle for fleet management, managers can offer employees the ideal support they anticipate and deserve, thus keeping productivity levels high.

Enhanced Security

Extending your fleet’s life cycle beyond their capacity and quietly suffering through their deteriorating efficiencies means missing out on safer vehicles for your drivers.

Getting trucks with more advanced safety features like forward-collision warning systems and automatic emergency braking keeps your drivers happy and your assets secure.

Lower Fuel Use

Excessive fuel use is not a desirable thing for fleet organizations: it piles on to the company’s operating expenses and also harms the environment.

Vehicle replacement cycles ensure that older vehicles consuming too much gasoline and not offering peak performance are replaced by new vehicles with better miles per gallon.

How To Finalize The Best Vehicle Replacement Strategy

Determining a replacement cycle for your fleet could lead to long-term savings. However, designing a detailed vehicle replacement strategy can be both daunting and overwhelming.

If you have lost all hope of seeking out the most beneficial replacement cycle for your fleet and don’t know where to start, we’ve got you covered with these simple tips.

Look At Vehicle Specifics

Start by looking at the typical categories: the number of years you’ve owned the truck, the mileage, monthly/annual repair costs, and the model of the vehicle.

Factor in extras like installing driver cams and custom-made features. These accessories add to your replacement costs should you need to install them in your new vehicle, too.

Turn To Fleet Tracking Devices

If you haven’t already, you should get started on fleet tracking and telematics by installing GPS devices.

The data from these devices can give you key insights into vehicle performance and point towards specific issues that may influence your final decision.

The tracking system collates and creates a simple report, so you get an overview of your vehicle’s annual maintenance expenses, fuel efficiency, compliance with inspections and safety regulations, and downtime.

Change Your Perspective

In a bid to reduce net costs, fleet managers might opt for an extended replacement cycle. They may delay buying newer models or prolong their lease terms to make the vehicle last longer.

Postponing replacement might seem like the cheaper alternative now, especially from a corporate vehicle budgeting standpoint. But interestingly, this strategy is more likely to increase your costs.

Older vehicles come with higher maintenance costs, and finding manufacturer-approved parts for outdated models is also next to impossible. Plus, these trucks may be out of warranty.

Since these factors often add to your overall fleet maintenance expenses, the winning strategy, in the long run, is to replace older trucks with newer, more efficient, and more advanced vehicles.

Vehicle Manufacturer Incentives

Speaking of financial savings, some vehicle manufacturers provide customers with incentives to get them to buy their newer products. These incentives include exclusive lease offers and discounts.

Fleet managers considering getting a new vehicle should take advantage of these aggressive deals to give their fleet a much-needed facelift. Competitive pricing can prove beneficial for your replacement strategy.

Tune Into The Needs Of Your Business

Apart from maintenance costs, it is prudent to create your vehicle replacement policies with the requirements of your business in mind.

If you’ve noticed that some vehicles in your fleet are more often than not left unutilized, chances are you don’t need as many trucks to keep your fleet operations running smoothly.

This stands in contrast to fleets that have too few vehicles and might be overworking their trucks (and drivers) to the point of impacting their resale value down the line.

Even if you’re satisfied with your current vehicle distribution, you may need a bigger fleet size one day, so consider your unique business needs and determine replacement cycles accordingly.

Concluding Comments

Remember: an older, inefficient fleet merely undermines the sacrifices you’ve made up until this point to keep your company at the vanguard and lower its operating costs.

Devising a replacement cycle strategy that complies with your business and investing in competent vehicles is the way to grow your fleet business as quickly as possible.

Managers can use fleet management software to determine the performance and utility of their existing vehicles and analyze which strategy offers the best returns on investment.

It’s best to update yourself with the right knowledge of newer truck models, competitive pricing and incentives, and technology systems that can give you access to a robust and productive fleet.

AUTOMOBILE

Evans Service Station: Car Care Needs

Evans Pitstop is the best place to get car parts and accessories, and we’re glad you’ve found us. We offer everything you need to improve your driving experience, whether you’re a seasoned pro or a novice. Your automobile requirements will be met here, from top-notch products and services to knowledgeable guidance. Evans Pitstop is proud of its staff’s extensive knowledge, skill, and commitment to delivering superior service to each and every one of its clients.

Evans Service Station: Better Road Trips Guaranteed

Evans Pitstop cares deeply that your time spent on the road be relaxing and risk-free. We have a variety of options to improve your car’s efficiency, looks, and usefulness. Evans Pitstop shines in many ways; let’s look at a few of them:

Increased Performance:

The Key to Realising Your Full Potential

Evans Pitstop is the place to go if you want to get the most out of your car. We have a wide variety of enhancements available that will make your car run better than before. Our trained mechanics will assist you in making the best upgrade decisions, whether you’re looking to modify your engine, install a new exhaust system, improve your suspension, or replace your brakes.

Statement Accessory Style

Evans Pitstop recognizes the value in letting your car reflect your unique style while you’re out on the road. That’s why we have so many exterior trim pieces for you to use as you see fit on your ride. We have everything you need to make heads turn, from attractive body kits and eye-catching decals to fashionable alloy wheels and unique lighting solutions.

Repairs and Upkeep: Keeping You Mobile

Keeping your car in top shape requires timely inspections and repairs on a regular basis. Evans Pitstop offers a wide variety of auto repair and maintenance options to keep your car in tip-top form. Our expert technicians have access to cutting-edge equipment, allowing them to quickly identify and resolve any problems that may arise. We can handle everything from a simple oil change and tyre rotation to a complete engine overhaul.

Protect the Charm with Car Care Products

Evans Pitstop has several premium car maintenance items available to help you keep your automobile in showroom condition. Our car care solutions, ranging from high polish and waxes to interior cleansers and protectants, can help you keep your car looking like new for years to come. on addition to helping you select the best items for your needs, our team is also well-versed on the best ways to care for them.

Accessories for Automobiles: Adding Convenience and Relaxation

Evans Pitstop knows how important it is for you to have a pleasant and hassle-free time behind the wheel. That’s why we have so many different kinds of auto parts and accessories to make your ride even better. We provide everything you could possibly want or need, from cutting-edge navigation systems and entertainment features to convenient storage alternatives. Our professional staff is here to help you find the perfect accessories to complement your wardrobe.

Conclusion

Evans Pitstop is the best place to go for all of your car care requirements. You can trust that your time behind the wheel will be nothing short of outstanding thanks to our extensive inventory, knowledgeable staff, and dedication to your complete pleasure. Our knowledgeable staff can help you improve your car’s performance, update its aesthetic, or keep it in excellent condition. Come see the difference for yourself by stopping by Evans Pitstop today.

AUTOMOBILE

How to Take Care of your 2020 Corvette

Keep your 2020 Corvette running smoothly and growling proudly for years to come. There’s nothing worse than rust or engine trouble with a sports car, so protect your investment and learn to protect your car from the elements. Shop for car covers, routine maintenance and learn how to care for your car cover. Don’t let your 2020 Corvette show signs of age, but keep it lovingly maintained with these products and maintenance steps.

Use an Indoor Car Cover in Your Garage

Pick up an Outdoor Cover

In emergency situations, there comes a time when your sports car must brave the elements. Thankfully, a custom outdoor car cover can shield your Corvette from rain, falling leaves, tree sap, and other contaminants. Pick up a cover that’s UV blocking so you don’t fade that beautiful paint job.

An outdoor cover isn’t a perfect solution, but it will prevent any scratches, UV damage, and light rainfall. Look for ways to keep your sports car stored indoors, particularly for long-term storage. Thankfully, this weather-resistance, breathable covers can handle the most common dangers to your paint job.

Wash and Wax Your 2020 Corvette

Routine washing and waxing protect automotive paint from wear. Washing removes dirt and contaminants that may scratch, stain or fade your paint. Waxing provides a reliable coating that is scratch, smudge and fade resistant.

In between washes, pick up a premium car duster. These handy tools don’t require water or soap and wipe off any dust or light debris that may otherwise damage your paint or diminish from the flawless look of your ride.

Get a Tune-Up and Oil Change

If you don’t drive your Corvette daily, it can be difficult to remember routine maintenance steps. Your sports care requires the same routine maintenance as your daily commuter, so be sure to keep up on changing your oil and other maintenance tasks. Stop by a reliable mechanic to ask about a tune-up or other preventative maintenance.

Check Out Your Brake Pads, Battery and Other Maintenance

Even a Corvette needs a new set of brakes once and awhile. Don’t let grinding, inefficient brakes hold your ride back, but keep up on other maintenance tasks that aren’t as common. Inspect your brakes, battery, muffler, and tires for signs of wear and pull into your trusted auto shop for a full-service repair.

Keep your Corvette Safe

Don’t wait until your sports car gets scratched and dinged before you protect it from the elements and the outdoors. Paint touch-ups and bodywork can be costly repairs, so invest in affordable Chevy Corvette car covers today to stay safe wherever you drive. Keep it covered in your garage and take an outdoor cover with you when you park at work for the ultimate in complete car protection.

AUTOMOBILE

Tech Trends That Are Transforming the Global Automotive Industry

Over a million plug-in vehicles roam the United States today, according to Carsurance.net. In fact, there are over 20,290 public vehicle chargers in California, which outnumber the total EV charging stations in six states combined. This is not surprising given that many consumers are looking for alternative solutions to diesel-powered vehicles.

Solar Powered Vehicles

The concept of integrating solar panels on the roof of a vehicle is not new, but its technological impact is minimal. Nowadays, you can ride vehicles that get some extra juice from the sun, such as the Karma Revero and Toyota Prius. You can find out more about these vehicles by checking out reviews on their reliability, quality, and driver experience from reputable sources. However, things will likely change as manufacturing companies are developing sunlight-capturing tech that is not only efficient but cost-effective too.

Monitoring Drivers With Biometrics

Avatar-inspired vehicles will take some time before it becomes road-worthy, but some of its key tech may debut soon like biometrics. Biometrics will help vehicles monitor drivers and passengers long before full automation becomes a reality. This tech will help drivers stay focused on the road, enhance safety mechanisms in the vehicle when a car crash occurs, and even customize infotainment too.

Affordable Lidar

Laser radar is said to be the key to our self-driving future, according to Elon Musk. But the cost of this technology is too high at the moment. Laser radar works together with other sensors such as long-range radars and cameras to help cars and trucks to “see” more in the long run. The goal here is to bring down the cost of Lidar down to make it more affordable for all car companies to use on their vehicles.

Car tech trends are always something to look forward to. These technological advances help make our lives more comfortable and convenient while we are on the road. From customizing our infotainment to equipping our vehicles with affordable lidar, automating our vehicles is closer than we think.

-

Marketing1 year ago

Marketing1 year agoHow Often Should You Publish on a Blog?

-

Technology1 year ago

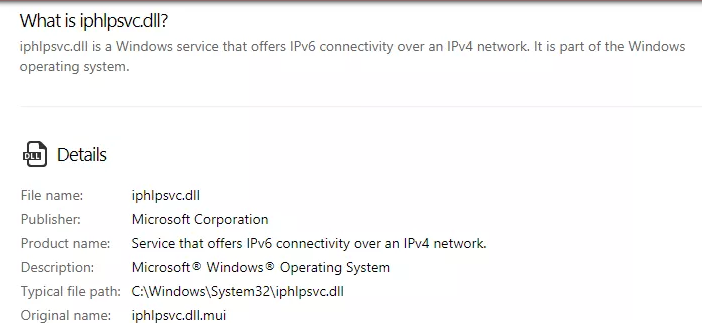

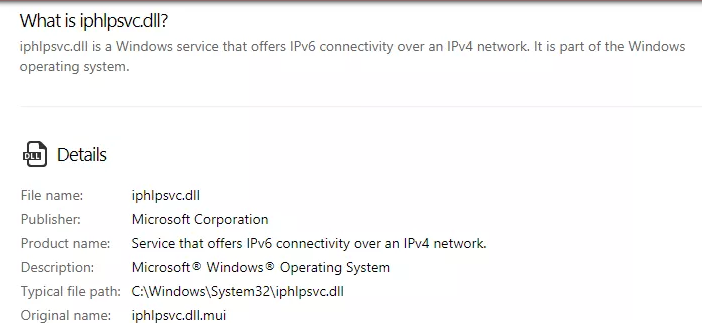

Technology1 year agoIPHLPSVC Services Tuning? Windows 7/10

-

Technology1 year ago

Technology1 year agoHow AI Can Transform Healthcare

-

REVIEWS1 year ago

REVIEWS1 year agoBest Gaming Communities Like F95zone

-

OUTDOOR1 year ago

OUTDOOR1 year agoColoring Black and White Photo at Home

-

Technology1 year ago

Technology1 year ago5 Best React JS UI Frameworks for Swift Prototyping

-

REVIEWS1 year ago

REVIEWS1 year agoAll You Need to Know About KissAnime – Is it Safe and Legal?

-

GAMING1 year ago

GAMING1 year agoPick N Mix: A Slots Adventure for Everyone